Foundry material industry is an advantageous and pillar industry of the Group. The annual output of furan resin, the leading product, is 150,000 tons, ranking the first in the world; Filter products breaking the foreign monopoly have been recognized as the National Torch Program key high-tech products by the Ministry of Science and Technology, ranking the 1st in Asia for production and sales volume; With more than 100 varieties of auxiliary foundry materials, including cold-box resins, pre-coated sand phenolic resins, alkaline phenolic resins, coatings, curing agents, inorganic binders, exothermic-insulating sleeves, and melting materials, Shengquan Group has structured a complete auxiliary foundry material and product system. These products, with globally leading quality, are widely used in the production of castings for automobiles, ships, aircrafts, wind power, general machinery, precision instruments and high-grade precision castings for export, and have been exported to more than 50 countries and regions.

By adhering to the concept of green and low-carbon development and the cooperation concept of “one-stop procurement and all-round service” and relying on the core technologies, Shengquan Group can provide a series of services such as product development, product application, process optimization and environmental protection and management, and offer technical support for stable and efficient production of customers. In the industry, Shengquan Group takes the lead in launching products and technologies such as low VOC furan resin, ultra-low addition cold-box resin, double layer composite filter, alkaline phenolic resin sand reclaiming technology, and workshop flue gas treatment. Through industrial chain collaboration and innovation, Shengquan Group is making contribution to the high-quality development of the industry.

Development History

Honors & Qualifications

System Certification

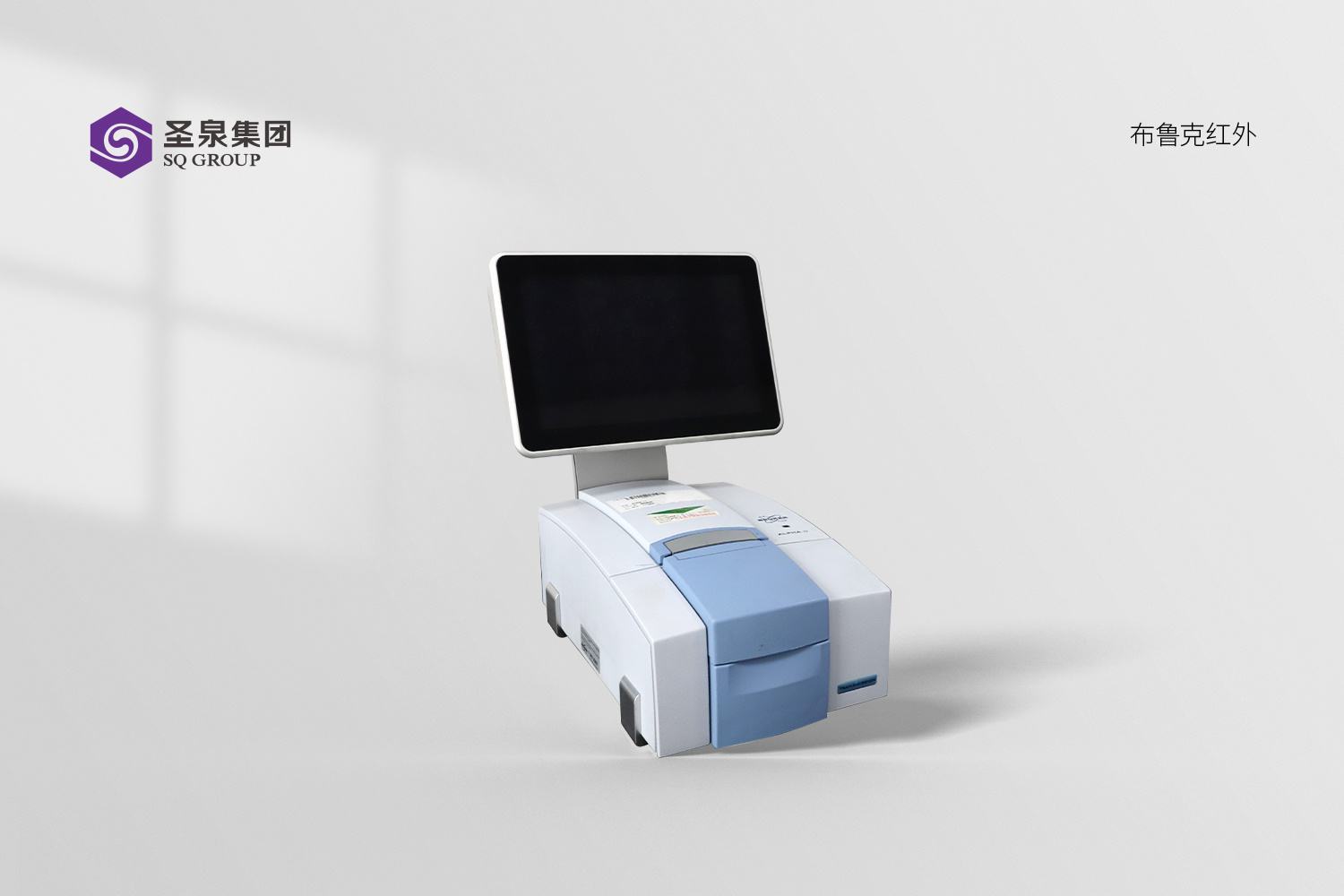

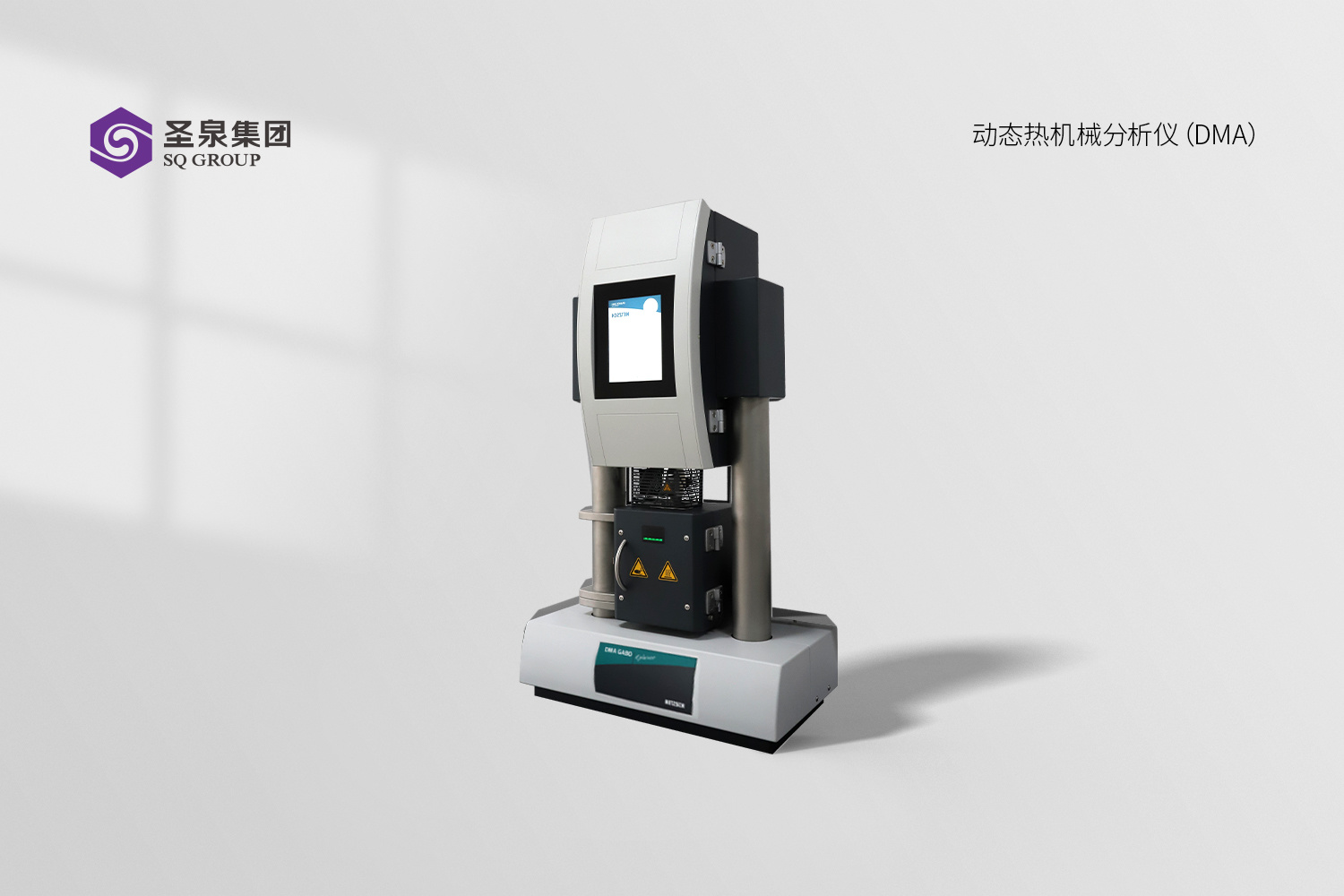

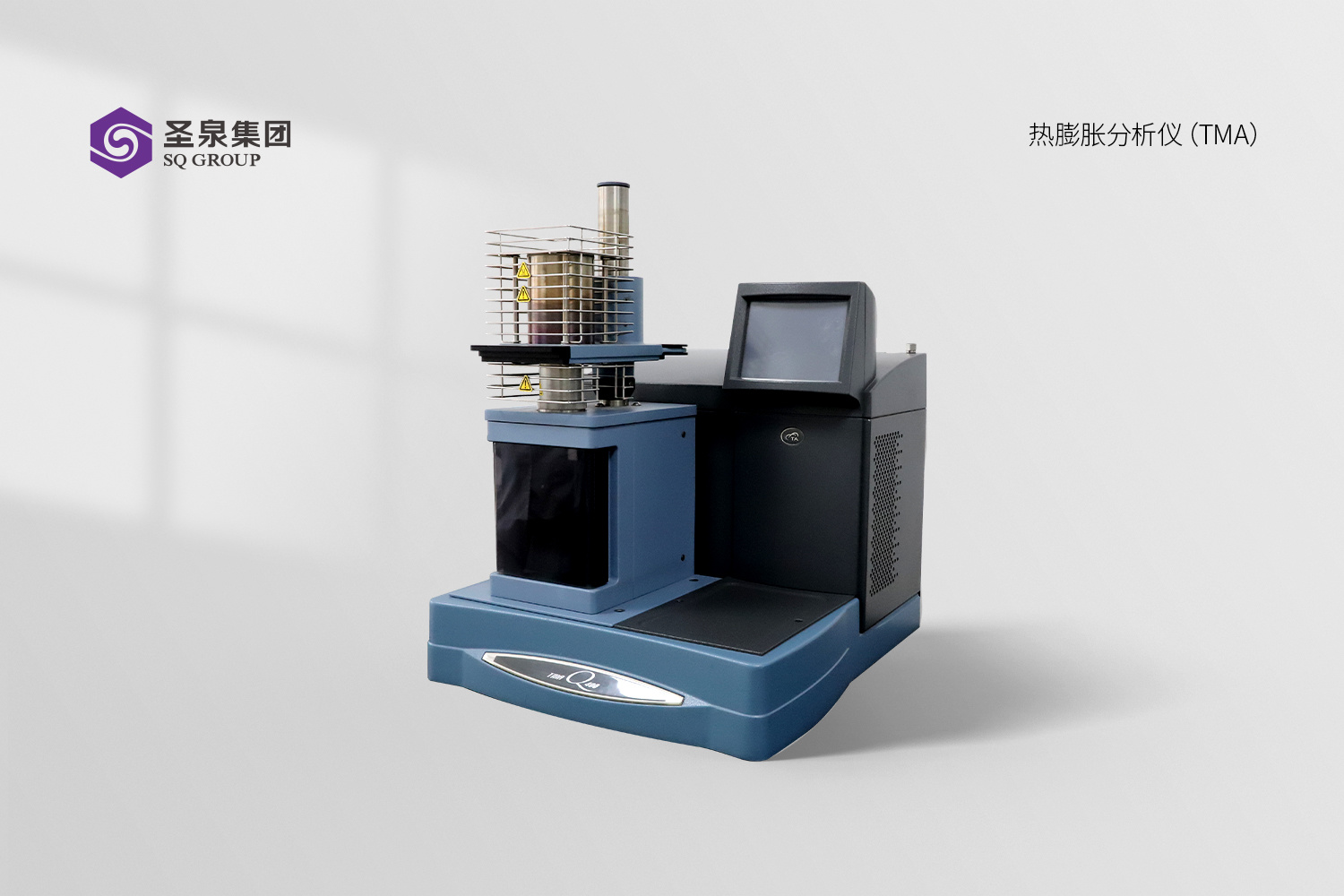

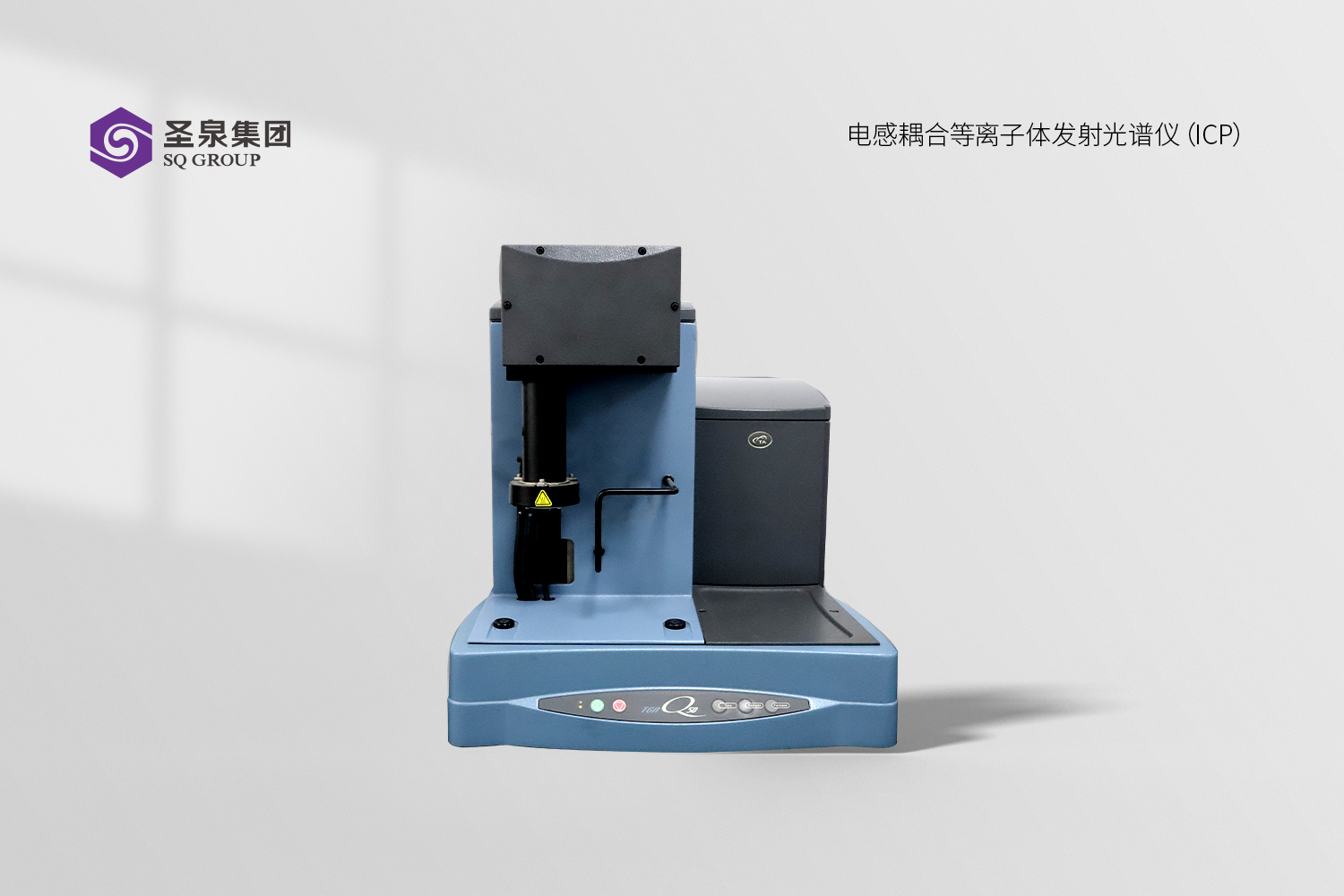

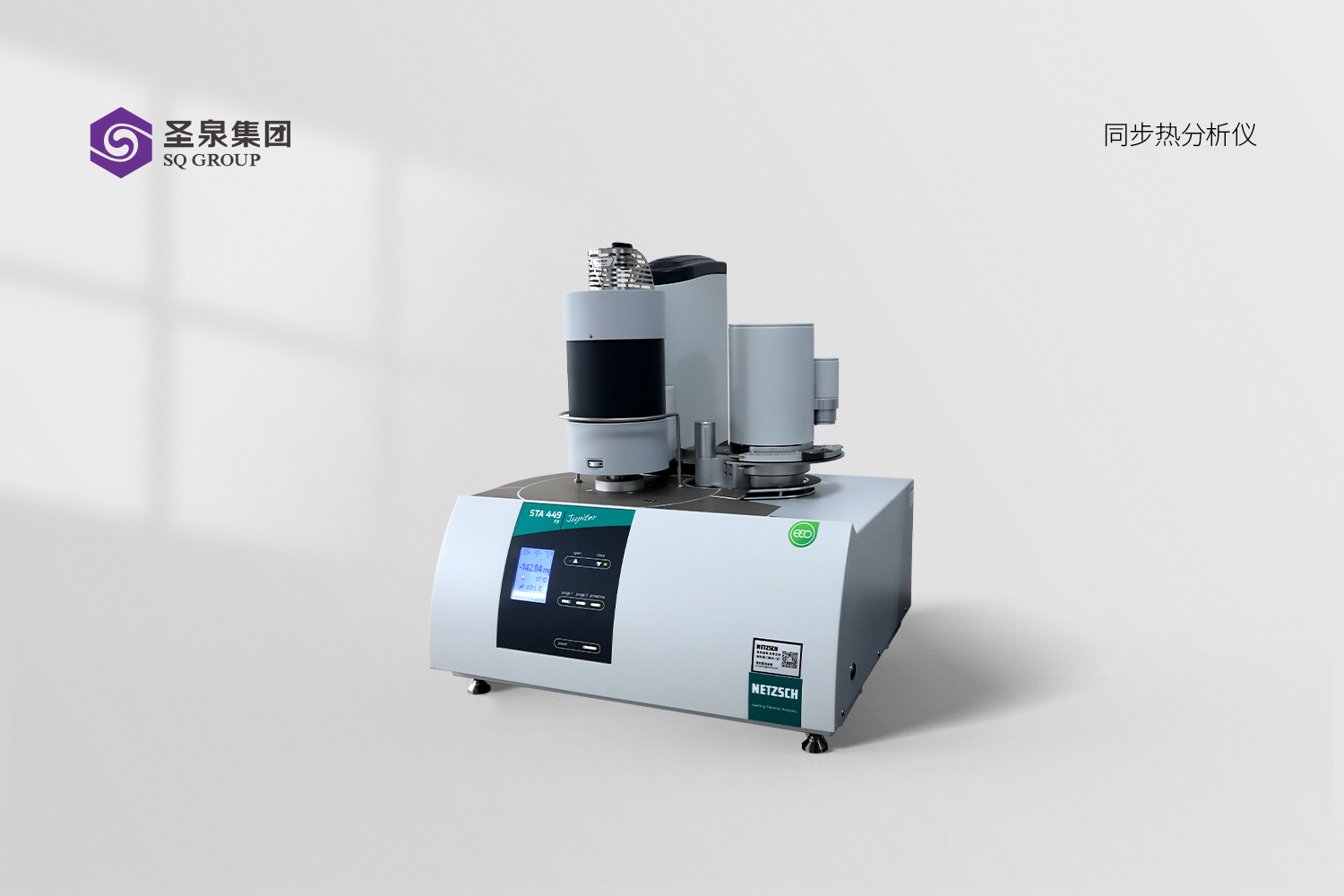

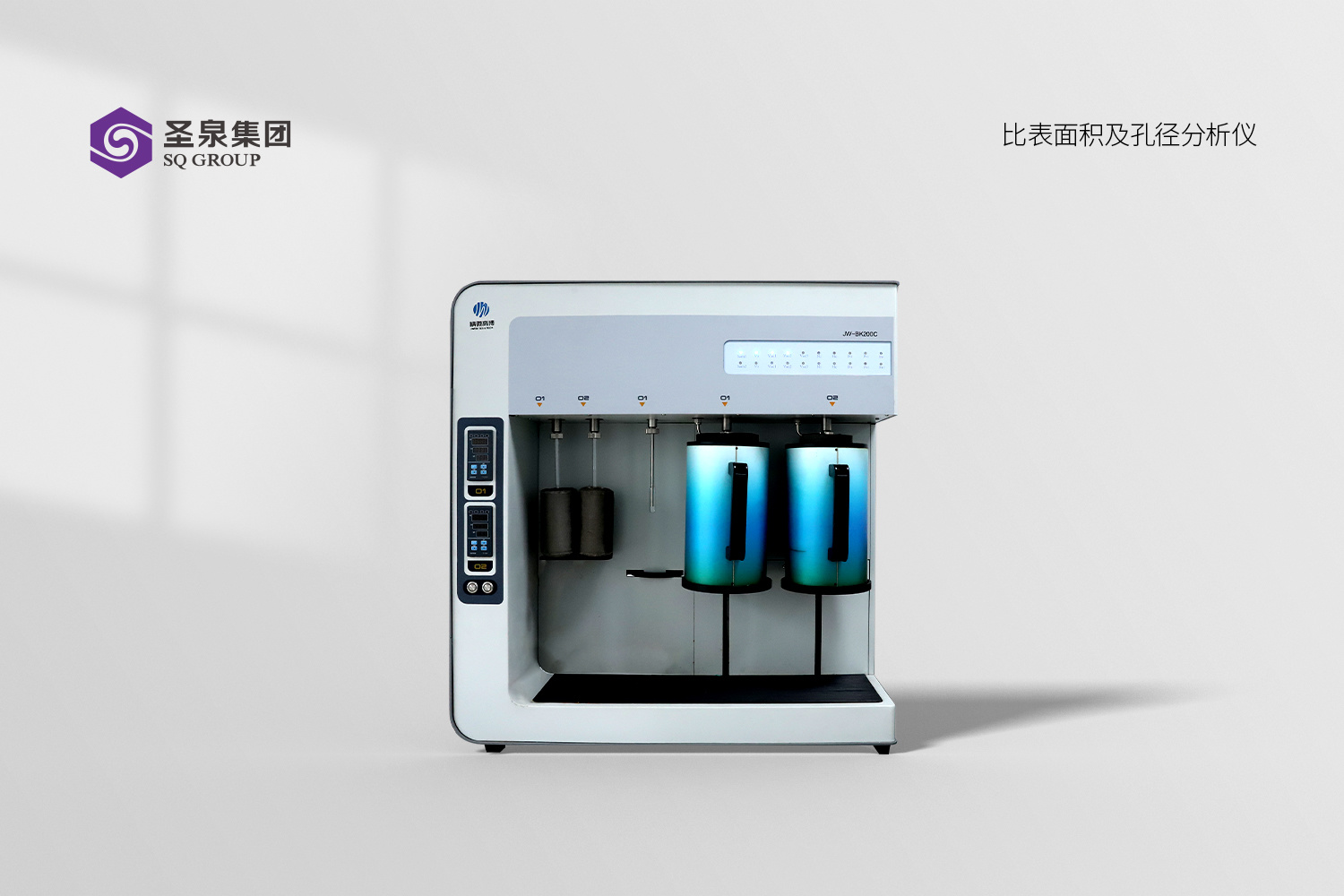

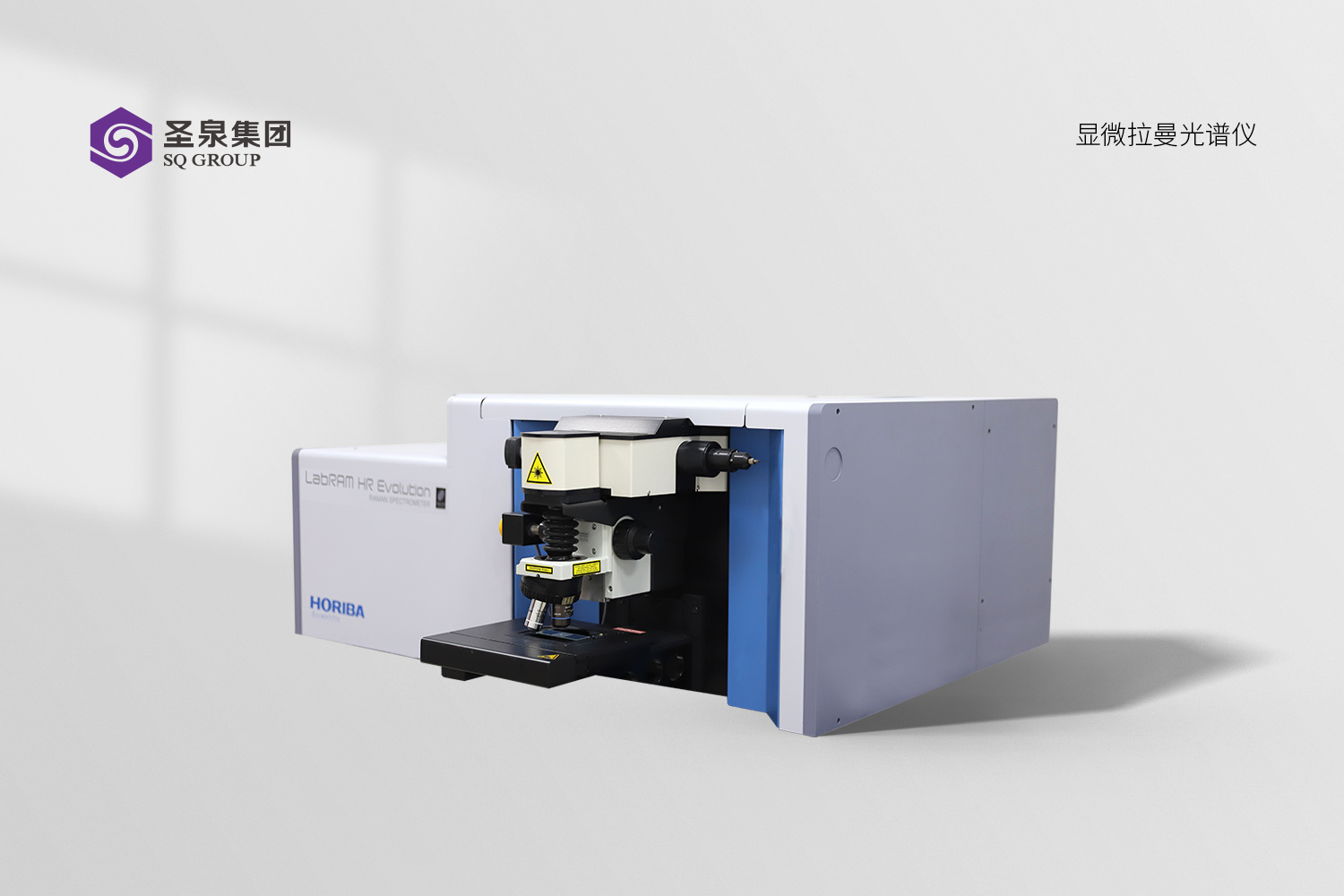

Inspection Equipment

Technical Support

Partners