After 40 years of efforts, Shengquan Group has developed the "Shengquan method" integrated biorefinery green technology. The green, efficient and energy saving technology overcomes industrial problems such as separation of cellulose, hemicellulose and lignin in biomass, biocatalytic synthesis, fermentation process and efficient cellulose conversion, lignin cracking and new xylose applications, and thus achieve high quality utilization of the three components, in which way hundreds of products can be produced from straws.

The cellulose can be used to produce pulp, dissolving pulp, nanocellulose, fuel ethanol, biomass graphene, etc., with the pulp further used to produce degradable green products (such as pulp molding). The hemicellulose can be used to produce furfural, xylose and L-arabinose, while the Lignin can be used to produce road asphalt emulsifier, dye dispersant, biojet fuel, xylofuran resin, degradable plastic film, etc. This green technology finally breaks the dependence of related products on fossil raw materials for a long time and foreign monopoly, and furthermore, the charcoal obtained by this process, featured with high calorific value and less ash, can replace coal as a chemical raw material, with extensive application range. The process will really make sufficient use of straws and realize the co-development of biomass chemical industry, petrochemical industry and coal chemical industry.

“Shengquan method” integrated biorefinery green technology is a technology with true origin innovation at the international level. At present, Shengquan Group is the only enterprise mastering this technology in the world, and has applied for 245 invention patents, of which 112 have been granted. The technology has been included in the Green Technology Promotion Catalog of the National Development and Reform Commission, and spread in the whole China. At present, the world's first 1-million-ton level “Shengquan” integrated biorefinery project (Phase I), invested by Shengquan Group, has been completed in Daqing, Heilongjiang.

Daqing Shengquan 1 million t/y integrated biorefinery project in Duerbote Economic Development Zone, Daqing City, one of the top 100 projects in Heilongjiang Province, is designed to process various straws of 1 million tons per year. The whole project covers an area of 660,000 square meters and a construction area of 219,000 square meters, and its construction is divided into 2 phases, with the Phase 1 Project started in 2019 and completed now, and Phase 2 Project at a planning stage. Along with the completion of Phase 1 Project, all production processes are ready, and the main products include base paper (including pulp), furfural, acetic acid, charcoal, etc.

This project has solved the problems of biomass utilization technology, including low utilization rate of raw materials, unsatisfactory environmental protection and economic efficiency, as well as environmental pollutions caused by straw burning and uncontrolled piling. In addition to reducing dependence of social production on fossil fuels, this project outputs a series of biological base materials with environmental advantages, and provides employment opportunities for farmers. It is an important demonstration for realizing the carbon peaking and carbon neutrality goals, protecting clear water and green mountains, implementing the rural revitalization strategy and promoting industrial transformation and upgrading.

Development History

Honors & Qualifications

System Certification

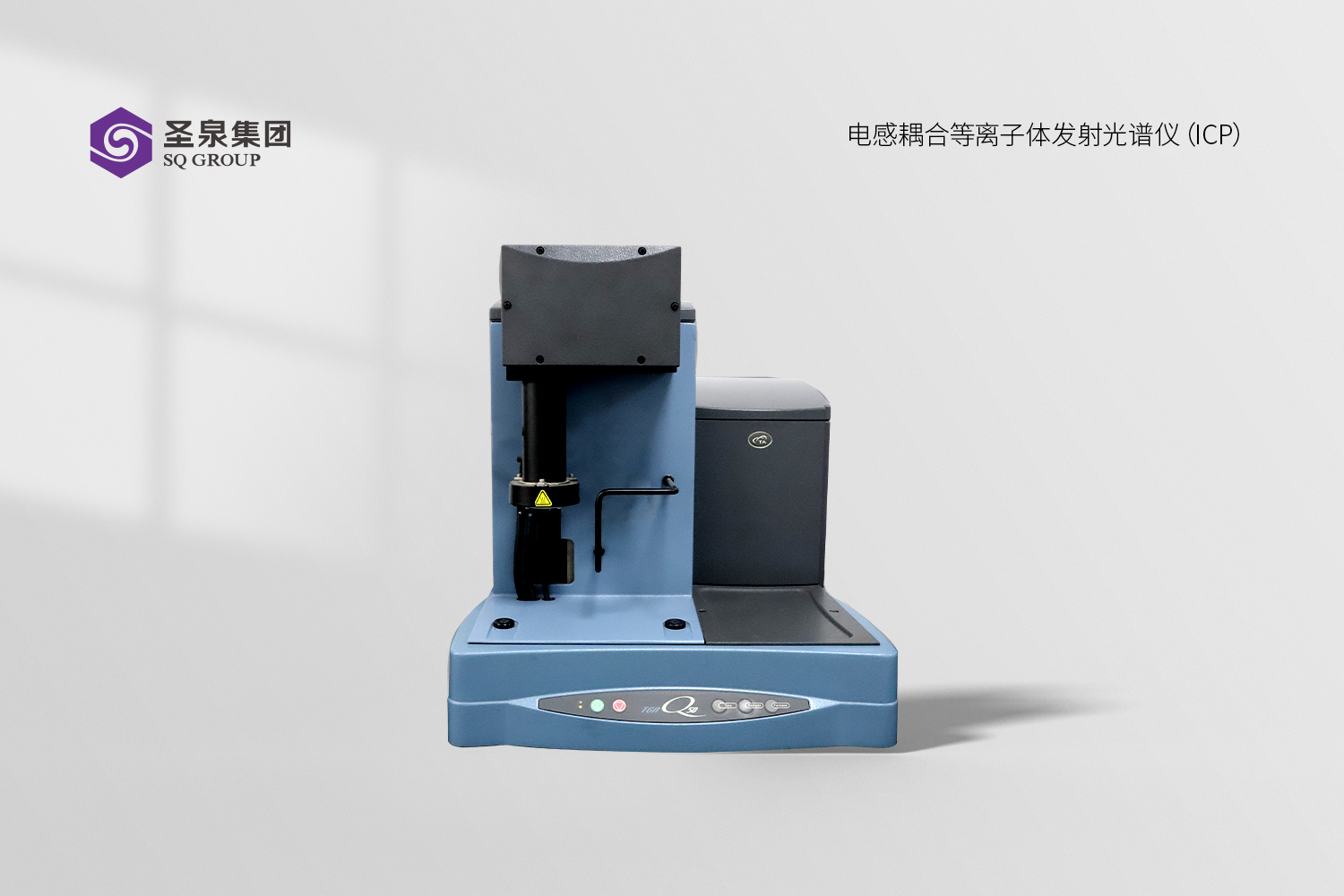

Inspection Equipment